Every rider knows the moment: a muddy trail, water pooling deep, and that split second of choice. Tiptoe around or charge straight through? With an ordinary e-bike motor, hesitation creeps in. With PREETO’s IP67-certified drive, hesitation disappears.

Think of IP67 like a fortress gate for a mid-motor. Dust, mud, and water—it all pounds against the walls, but nothing gets inside. The engine remains the beating heart of the ride, pumping out power no matter how muddy riders get, no matter the wash-down after the ride. For riders, that means freedom: to push harder, to ride in any weather, because riders can trust that the machine will survive the elements.

In this story, PREETO’s engineers pull back the curtain. They reveal how careful sealing, clever design, and relentless testing make IP67 more than just a technical code.

What steps does it take to achieve the IP67 standard?

“Meeting the IP67 standard is a system-level challenge that spans design philosophy, materials engineering, sealing architecture, precision assembly, and full-scale validation,” PREETO senior engineer Carlos Zhou says.

IP67 in Practice: What Does It Mean?

The IP67 rating, defined by the International Electrotechnical Commission (IEC), sets strict criteria for dust and water resistance:

“6” (Dustproof): The highest dust protection grade, ensuring complete prevention of particle ingress.

“7” (Waterproof): The ability to remain watertight after 30 minutes of immersion in one meter of water.

While the definition appears straightforward, the engineering behind it is highly demanding, pushing the limits of both design and production.

What are the five engineering Pillars of PREETO Motors’ IP67 rating

1. Design: Risk Prevention at the Source

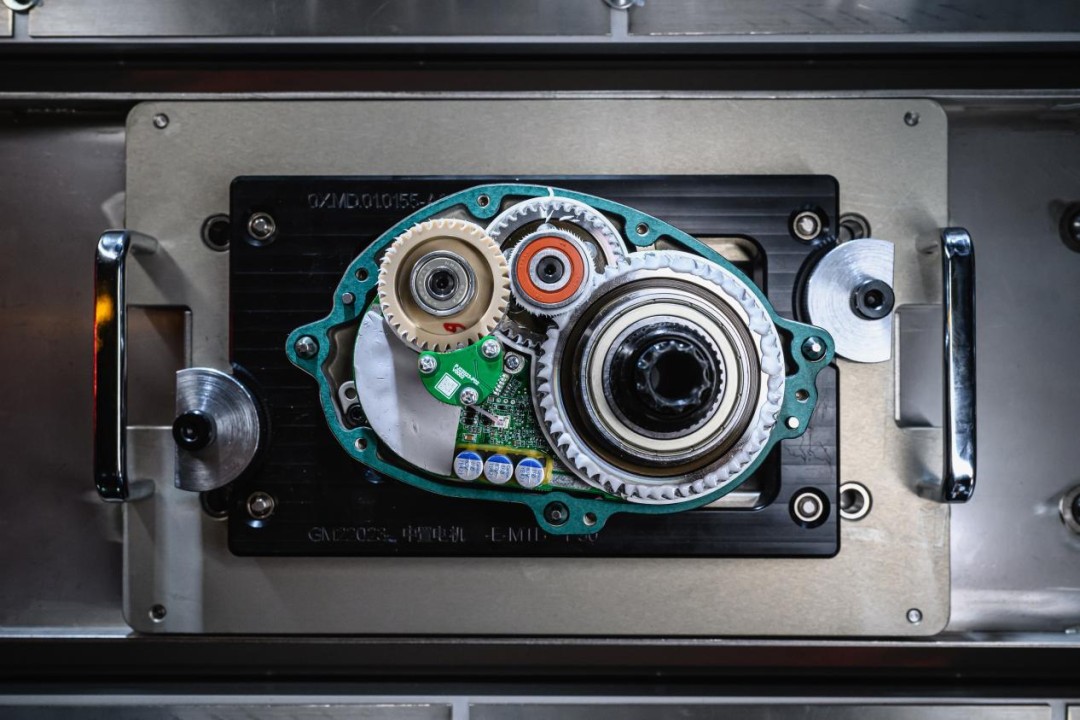

“The first principle of waterproofing is to eliminate openings wherever possible,” explains Carlos. PREETO’s mid-drive motors employ a highly integrated die-cast housing that drastically reduces seams.

For unavoidable interfaces—such as housing joints, connector ports, and pedal axles—surface flatness and smoothness are controlled to micron-level tolerances. “Only with this precision can seals deform under pressure to close micro-gaps and ensure lasting tightness.”

2. Materials: Strength Meets Corrosion Resistance

The motor housing is crafted from magnesium-aluminum alloy, chosen for its unique balance of high strength, lightweight properties, and corrosion resistance.

“The shell must maintain rigidity under water pressure without deformation,” says Carlos. “Only then can the sealing surfaces remain stable.” This material choice ensures durability against outdoor impact, vibration, rain, and sweat exposure.

3. Sealing Technology: Tailored Static & Dynamic Solutions

PREETO adopts a dual sealing strategy:

Static Seals: Applied at housing joints and connectors using custom gaskets or injection-molded adhesives, tightened with balanced torque to ensure uniform compression.

Dynamic Seals: For rotating axles, PREETO deploys a dual-layer system—a skeleton oil seal for primary protection and an O-ring for secondary reinforcement, working together to block both liquid ingress and dust intrusion.

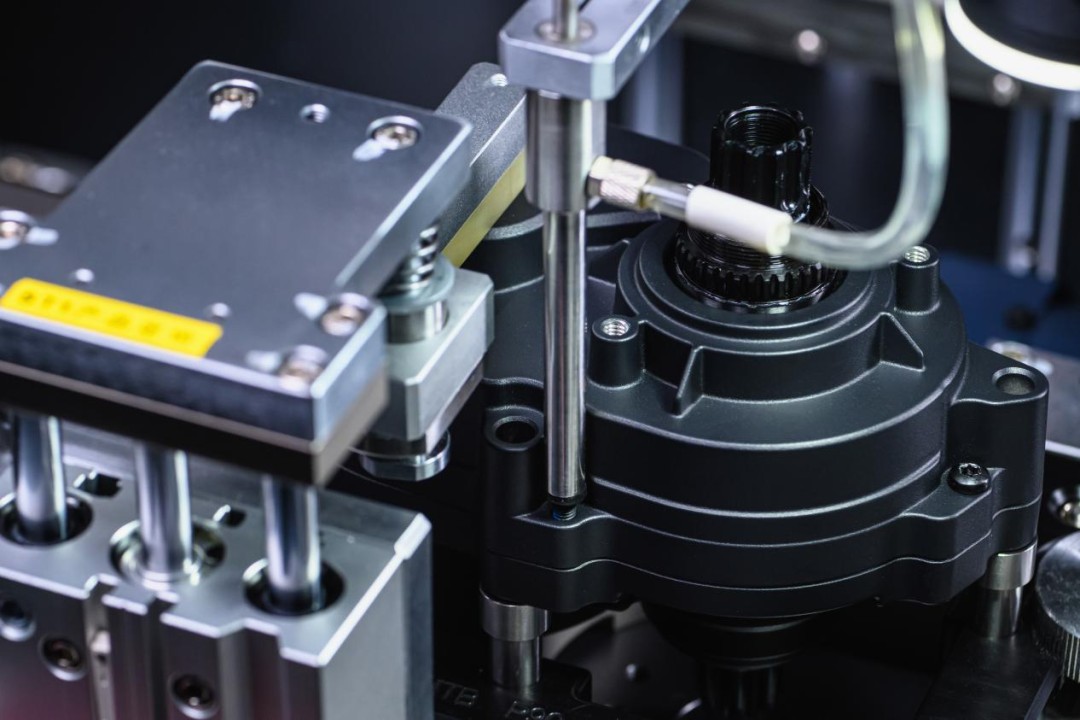

5. Assembly Process: Precision for Consistency

“The best design is meaningless without disciplined assembly,” notes Carlos. PREETO enforces strict fastening protocols: adequate screw counts, cross-pattern tightening, and torque precision.

Semi-automated production lines and robotic screwdrivers standardize these processes. “In mass production, consistency is the true guarantee of reliability.”

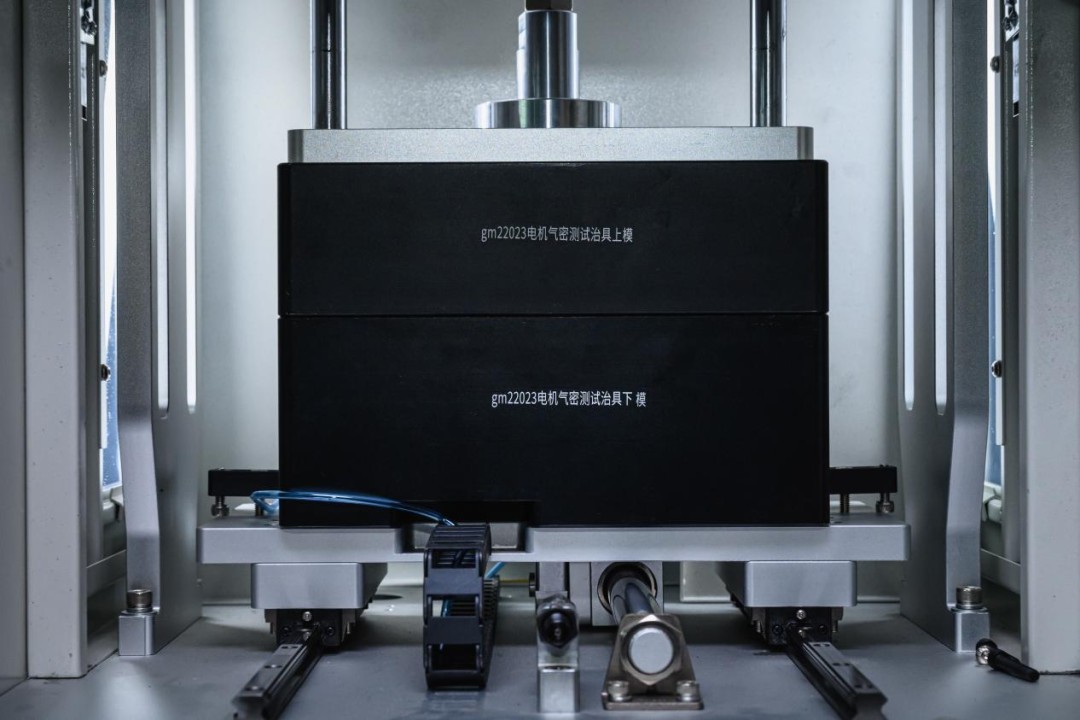

6. 100% Airtightness Testing: Zero Tolerance for Leakage

Every motor undergoes full-unit airtightness testing before shipment. Each unit is exposed to positive and negative pressure cycles, with sensors detecting even microscopic leaks.

“Even the smallest leak is unacceptable. PREETO’s policy is zero leakage at delivery,” stresses Carlos. Though costly, this approach underpins PREETO’s uncompromising commitment to quality.

“At PREETO, IP67 is not just a checkbox; it is part of PREETO quality values that the company commits to. It represents a system-level framework that runs through design, materials, manufacturing, and validation. More than a rating, it reflects PREETO's engineering philosophy and customer values: absolute reliability for every rider. All efforts lead to one purpose—to ensure that in any riding situation, riders don’t have to think and just enjoy the pure freedom of riding.”

Media Contact

Company Name: ZW Drive GmbH

Contact Person: Juergen

Email: Send Email

City: Ottobrunn

Country: Germany

Website: https://www.preeto.net/