PALMETTO, FL / ACCESSWIRE / January 6, 2025 / The Automotive Industry adoption of GDI (Gasoline Direct Injection) technology over the tried and true port injections all have been accustomed to for the past few decades that would last 200k plus miles with minimal care has resulted in a high percentage of catastrophic engine failures and internal parts failures. This has hit these light fleets consisting of light trucks, vans, taxis, Municipal vehicles hard as far as operating costs to keep them running and predictable as far as setting budgets based on the past technologies.

Unplanned down time and the ability to use for the time and miles they had been accustomed too has thrown this industry into a bit of the unknown. And has launched an era of class action suites against most all automakers worldwide. The issues:

GDI engines experience 8-12 times the amount of raw fuel pushed past the piston rings washing oil from the cylinder walls and diluting the already thin viscosities most specify to use, to the point of not being able to protect properly in as little as 1,000 miles when compared to the port injection engines they replaced. (Google: "GDI engine failures from excessive oil dilution class action" and simply add ANY automaker at the end to see how this has caused these premature failures. This also results in excessive oil consumption issues as the super diluted oil is easily pulled into the combustion chamber and "burned". But as the oil level may increase with the added fuel, many that maintain these vehicles are not aware how severe this is, until engine failure.

As GDI engines no longer have the detergent fuel spraying onto the backsides of the intake valves keeping them cool and clean, the coking deposits that accumulate bake into a hard crystalline form that is as hard and abrasive as sand. As these deposits shed, while most is expelled out the exhaust, plenty of the smaller particles are forced between the pistons and cylinder wall scouring, and making their way into the crankcase as well adding to the premature wear. As these are mainly smaller in particulate size than most oil filters can trap down to, increased wear occurs along with the fuel diluting the oil.

Oil can be considered to have reached "condemned state" in as little as 1,000-3,000 miles and if not drained and replaced at this point, engine failure can be not far behind.

And a related issue is the degradation in fuel economy as the thinned oil is drawn into the combustion chamber contaminating the air/fuel mixture and causing "knock" (detonation), the ECU will detect this knock and pull timing to protect the pistons, and the engine then operates a less efficiency and power and fuel economy suffer.

How has the industry responded? Aside from denying any of this was occurring early on, and then claiming they "addressed" the issues, they finally reduced the warranty period on these GDI engines from an industry standard 100k mile warranty to 36k miles reducing their exposure to long term liability. But for the average light fleet owner, that does little.

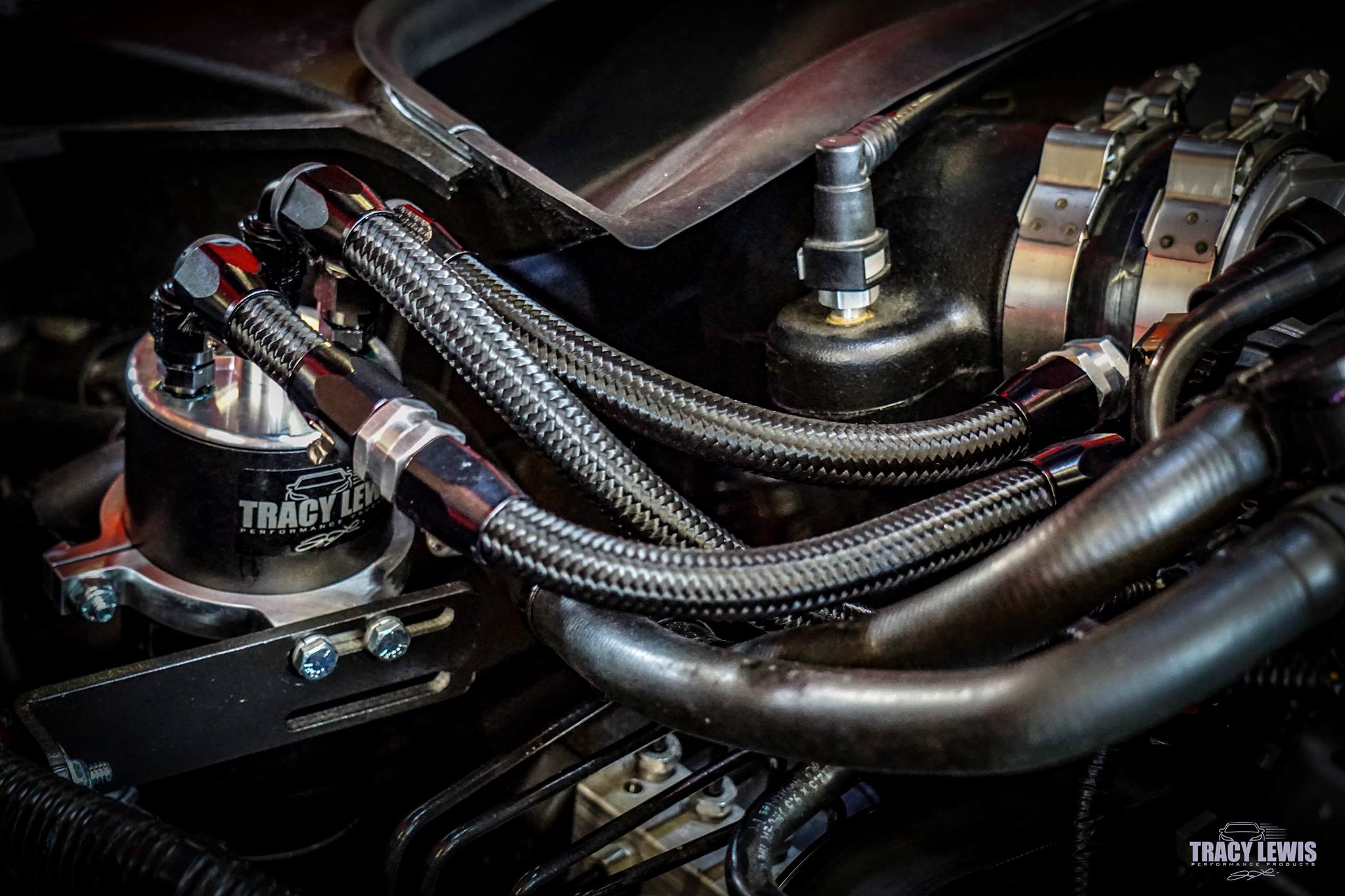

The Tracy Lewis Catch Can addresses the cause of these issues by providing full time vacuum based evacuation of these substances before they have a chance to settle and mix and accumulate in the crankcase. And it does so retaining a closed system that actually reduces tailpipe emissions by removing these before the combustion process, scrubbing the vapors to remove and contain these contaminants separately for proper disposal later. The engine oil remains clean and in comparable condition for 2-3 times as long so drain intervals can be extended (with regular oil analysis to monitor).

Wear is reduced to a minimum.

The intake valve coking, if the system is installed when new, or nearly new, prevents up to 85% of these deposits from forming to begin with.

Downtime is reduced to port injection engine levels.

And an unexpected benefit from the elimination of most oil vapor caused knock retard results in a minimum average gain of 10% in fuel economy (with many seeing 12-14% gain).

Fleet owners/managers that have at least 50 vehicles in their fleet and track all costs incurred (including fuel usage) can request a complete system to test to validate and verify the benefits at no cost and we will train their techs on all involved.

Average ROI can be achieved in 4-8 months depending on miles driven, and from there on out the cost savings realized is substantial.

Visit the website to learn more about the Tracy Lewis Catch Can.

About Tracy Lewis Performance

Tracy Lewis Performance started operations in 2010 with a focus on providing customers with high quality American made performance products.

Media Contact

Karen Lewis

apdeg@aol.com

9419813930

616h 17th St E

Palmetto, Florida

SOURCE: Tracy Lewis Performance

View the original press release on accesswire.com