When it comes to the unending search for efficiency, managing labor costs is a battle that warehouse and retail managers have been accustomed to. You have optimized the pick paths, provided incentives to teams, and provided barcode scanning.

However, you have a sense that your employees are wasting time on easy, menial tasks. It is not necessarily the effort of your team, as it is the technology you are dependent on: a barcode.

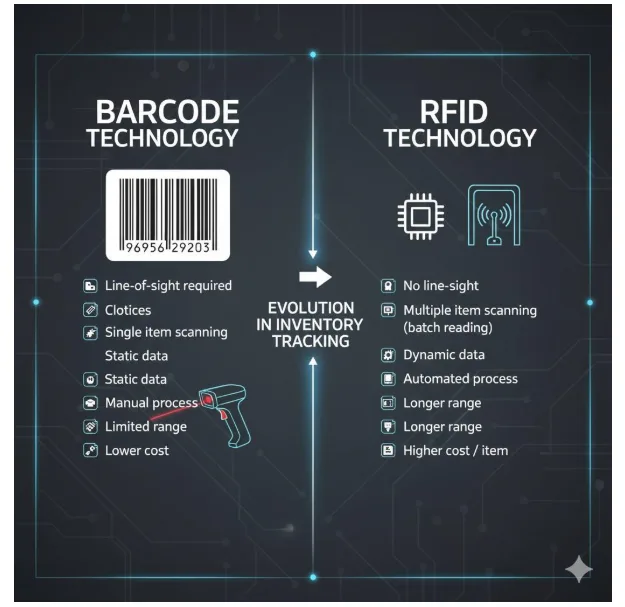

The barcode has been the inventory management workhorse for decades. It introduced a computerized stockroom and checkout. However, in the current day and age, where e-commerce is a requirement, the barcode is a limited resource; it comes at a huge cost to your work budget as a hidden tax. To know the future of efficiency, we should go beyond the Barcode. Talking to an expert will help you better understand RFID retail and its impacts on your business.

Line-of-Sight Scanning for Time Tax

The inherent weakness of barcode technology in a dynamic inventory setting is that it needs a line-of-sight, one-at-a-time scan. This basic reality causes a time-consuming series of activities:

a. Inventory Counting

Barcode Physical inventory count is an epic undertaking. An employee has to find each piece, place the scanner (or his/her body) in the right location, and cause a scan. In the case of a warehouse that has 50,000 SKUs, this may take days, which may demand huge amounts of overtime or a shutdown.

b. Bottleneck

Once a shipment has been received, the individual boxes and frequently the individual items within the individual boxes must be scanned to verify the shipment. There is a pallet of 200 mixed items, which can take an employee 30 minutes or more.

c. Pick-and-Scan Drag

In order picking, the fixed scan, confirm, move pick-and-scan cycle will add seconds to every pick. This translates to hours of dead time movement over hundreds of picks per worker per day.

d. Search Mission

Lost things are a nightmare. Locating a particular SKU that was misplaced within a 100,000 sq. ft. plant is a pure, unproductive labor expense (visual hunting).

All these tasks can be converted to payroll time. Worse still, it keeps your employees busy with these scans as opposed to more value-adding activities such as quality control, customer care, or solving complex problems.

How Can RFID Ensure a Complete Revolution?

Move to Radio-Frequency Identification (RFID). Bulk, simultaneous data capture is the main superpower of RFID. An RFID tag does not need to be visible, as opposed to a barcode. A single RFID reader may be able to detect dozens, even hundreds, of tagged objects instantly within its range, boxes and cartons, and without necessarily being able to see them.

That is not a side-whisker addition; it is a paradigm shift in terms of efficiency in labor. We have the same processes, but let us see how they differ:

1. Inventory Counting

Days to Minutes. A handheld RFID reader can also be carried by an employee who will walk an aisle and scan all items on both sides within a single pass. A 40 man-hour barcode inventory that used to occupy a full warehouse can be fulfilled in 2-3 hours using RFID. The labor saving is instantaneous and appalling.

2. Receiving

30 Minutes to 30 Seconds. When an item pallet of RFID tags is passed through a dock door portal reader, it can be checked. All of the shipping is figured during the time it takes to announce the pallet. No unloading, no personal inspection.

3. Verification Process

Checking With Admiration. Under RFID-enabled carts or zones, a pick will be confirmed as soon as it is placed in the cart- there is no requirement to locate and scan a barcode. This saves the needed seconds on every pick, and more orders can be made during a shift.

4. How to Find the Lost Inventory?

Finding Lost Inventory. Require 10 jackets of a given jacket? A handheld RFID reader has the capability of directing an employee to the point of location, and a 45-minute search is transformed into a 2-minute search.

RFID automates the physical labor data capture aspect. It saves the time taken to scan hours manually into seconds of automated collection, and your personnel are free to conduct themselves in areas that really need human judgment and dexterity.

Aspects We Must Consider While Implementing an RFID System

When implementing RFID, there are important aspects that should be considered.

RFID is a strategic investment in transitioning barcodes to RFID. The following points are the most important to consider:

a. Tagging Strategy

RFID tags (UHF) cost has reduced drastically. An emphasis is placed on the tagging point. The best level of granularity and advantage is tagging at the item level (apparel, electronics). In other industries, case-level or pallet-level tagging could be an effective beginning. It can be visualized in ROI: often, the savings in labor can cover the tag price in a short time.

b. Investment in Infrastructure

RFID readers (fixed portals at docks, aisles, or point-of-sale and handhelds used in mobile tasks) and RFID antennae will be required. The software layer – combining the deluge of RFID data with your existing Warehouse Management System (WMS) or Inventory Management System is very important. Select partners with solid middleware and integration.

c. Data Accuracy and Change in Process

With a proper implementation, RFID is almost 100% accurate in inventory. This precision makes a positive difference: you can now implicitly rely on your system inventory. This minimizes safety stock, eliminates stockouts, and enables new activities such as prohibited flash cycle counts during the day.

d. Warehouse Management

Omnichannel Efficiency: RFID gains significance in an omnichannel world. It allows proper Buy Online, Pick Up In-Store (BOPIS) fulfillment by ensuring that the item is indeed on the shelf. It also drives self-checkout systems in which a customer places an entire basket into an RFID-operated area to check out automatically, and does not require as much frontline labor.

Actions we must take to make the journey successful

1. Get Help from Experts

Boil not the ocean. Start with a high-impact, contained space- a fast-moving clothing department, your receiving dock, or a product line. Test and prove the ROI and get acquainted with the specifics in a simulated setting.

2. Focus on the Process

Pay attention to the Process, not the Tech. Only RFID is going to reveal the inefficient processes. Take the implementation as an occasion to re-engineer workflows. As an example, redesign your receiving area to direct goods around a fixed reader.

3. Prepare a Team

Connote RFID as a tool to rid the tedious work, but not a surveillance tool nor a substitute for employees. Make them a part of the pilot; their practical feedback cannot be accessed, and it makes them champions.

Some Final Key Aspects

Monitor pre- and post-implementation measures unambiguously:

- Time at work on inventory counts.

- Time per receiving shipment

- Pick rate (items per hour)

- Percentage of accuracy of the inventory.

- Hours that are wasted in looking for lost things.

It is a trap to think of labor as a cost that must be minimized. This is aimed at making the best use of each volunteer hour. Barcode scanning spends large percentages of those hours on mere data entry. RFID liberates that time. Try to choose the best RFID software platform to ensure quality service.

RFID changes your workforce by automating inventory intelligence. But s/he becomes a stock clerks who become an inventory analysts. Pickers would become fast fulfilment experts. You can invest the benefits of fewer routine tasks in business expansion, customer experience, and training your employees.

The revolution of the barcode was made. Now, it’s RFID’s turn. It is not just the issue of getting new technology but also about opening up the vast strategic potential of your greatest resource, your people, when you look beyond the barcode.

It is an investment in tags, readers, but the real investment is in the productivity, accuracy, and, finally, a more robust and lucrative enterprise. The futuristic scan is not a beep, but it is a symphony of data so silent and simultaneous that it is already present.