Material Revolution of cave stone technology

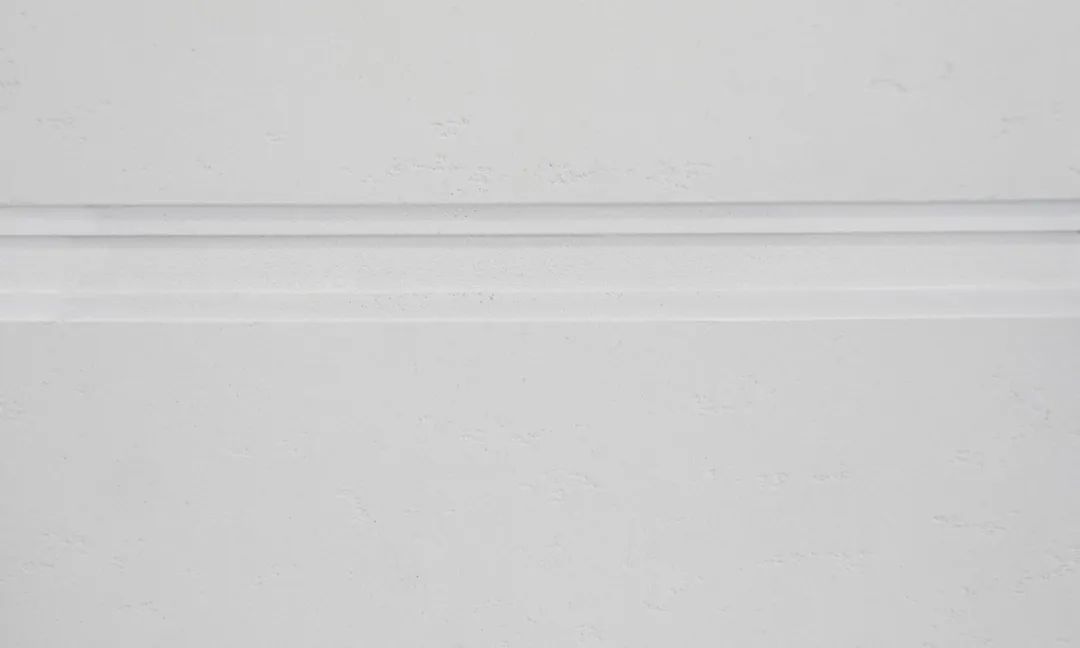

With the pursuit of natural texture and long-lasting performance of the building facade, cave stone is favored for its unique texture and historical feeling. However, the effect of travertine made by traditional emulsion coatings often shows fatigue under the test of time and environment -- fading, peeling and lack of weather resistance have become a dull pain in high-end buildings.

Sengu new materials, as an innovative force in the field of imitation Stone Paint, officially launched subversive products: inorganic dry powder coating wall travertine process! We abandon the traditional organic emulsion path, return to the cement-based inorganic origin, with the power of science and technology, not only perfectly reproduce the natural limestone hole rhythm and laminated texture, but also achieve a qualitative leap in physical properties, give its superior performance beyond stone.

Core Showdown: Inorganic Dry Powder vs. Traditional emulsion coatings, material nature of the differences

1.Different roots:

- Traditional emulsion coatings: organic polymer emulsion (such as acrylic acid, silicone-acrylic emulsion) as the main binder, mixed fillers, additives and so made. The essence is that the inorganic powder is coated by the organic matter.

- Sengu inorganic dry powder stone: with silicate as the core inorganic binder, carefully selected graded aggregate, mineral filler and functional additive composition. The essence is the reaction and condensation of inorganic mineral materials.

Two, the curing mechanism is different:

- Traditional emulsion paint: depending on physical drying film. After the moisture evaporates, the emulsion particles coalesce into a continuous film, which wraps the filler and adheres to the base layer. The film-forming process depends on the ambient temperature and humidity.

Cement + water → hydrated calcium silicate gel, etc. . This is a chemical reaction process, forming a hard, dense, and the underlying mineral composition of the microcrystalline structure similar. The strength increases continuously with hydration.

Process Improvement: more stable, more efficient, more controllable

Ease of construction:

- Traditional emulsion paint: mostly finished barrel paint, ready to use or simply diluted. Construction is relatively simple, but the base humidity, environmental temperature and humidity requirements are higher (low temperature and high humidity easy to affect the film) .

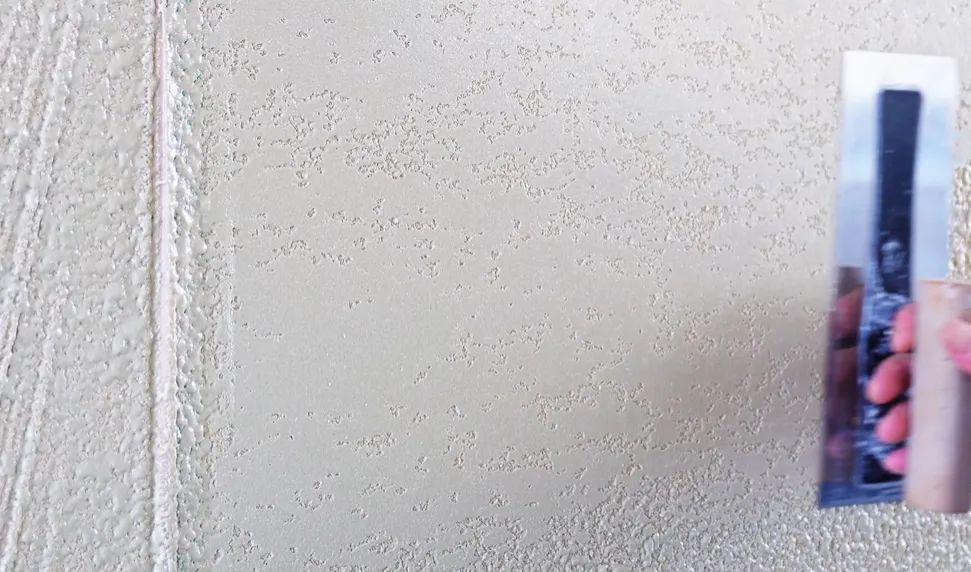

Sandgu inorganic dry powder stone: dry powder state storage and transportation, the scene according to the proportion of water mixing can be used. Ready-to-mix, no worry about storage deterioration. It is more adaptable to construction environment (especially low temperature)(hydration reaction can still proceed slowly at low temperature) .

Effect controllability:

- Both can use professional tools (e.g. cave rock rollers, knives, etc.) and artisanal techniques to shape the cave rock texture. Due to the good plasticity and thixotropy of inorganic dry powder, the texture molding is easier to control, and the pore shape is more natural and stable.

The core advantage of Sengu inorganic powder travertine technology: not only in beauty, but also in“Strength”

Excellent durability:

- Excellent water resistance: cement-based hydration products themselves dense hydrophobic, no organic film swelling, foaming, falling off worry. Excellent performance in long-term soaking or wet environment, effectively resist rain erosion.

- Super Alkali Resistance: it belongs to the same alkaline system as the cement mortar/concrete base course. It is perfectly compatible and will never be afraid of“Alkali corrosion”, completely solve the emulsion system may be due to the base back to the alkali coating blooming, pulverization, falling off the problem.

Ultra-high strength: the microcrystalline structure formed by the hydration reaction gives the coating extremely high hardness and compressive/impact strength. Far from comparable organic film, effective resistance to external damage, the protection of the wall.

Timeless colors:

Inorganic mineral pigments: the use of inorganic mineral pigments coloring, color from the mineral itself, non-organic dyes.

Never Fade: inorganic pigments have extraordinary weatherability (UV, high temperature, acid and alkali resistance) , color lasting stability, over the years, the style remains the same. Bid farewell to organic pigments due to ultraviolet decomposition caused by fading, yellowing.

The ultimate in environmental safety:

- Grade A fire prevention: the main components are inorganic minerals, which do not burn in case of fire and do not release toxic smoke. It reaches the National Building Materials Grade A non-flammable standard and escorts the construction safety.

- Zero VOC: no volatilization of organic solvents in the production and construction process, green and environmentally friendly, and protect the health of construction workers and residents.

Breathe “Breathe”:

The inorganic microporous structure has good permeability, allowing the natural evaporation of water vapor inside the wall to be discharged, effectively preventing the internal moisture accumulation from causing the coating to bulge and peel off, and keeping the wall dry and healthy.

Perfect integration with the substrate:

It has excellent chemical compatibility and physical affinity with concrete, cement mortar and other inorganic base due to its cement-based properties. The bond strength is high and durable, and it is not easy to appear interface peeling.

Sengu Commitment: From Nature, beyond nature

Sengu inorganic dry powder coating wall travertine technology, not only is the innovation of material science and technology, but also the persistent pursuit of architectural quality and artistic expression. We are well versed in the beauty of natural cave rocks and understand the stringent requirements of modern architecture for high performance, long life and low maintenance.

Select Morigo inorganic dry powder stone, you will get:

- the authentic texture of natural cave stone gives the building a unique artistic quality and sense of historical significance.

- Superior Performance of natural stone, withstanding wind and rain, and enduring the test of time.

- Reliable Guarantee of safety and environmental protection to provide safe guarding for buildings and users.

- lower long-term maintenance costs, once and for all.

Bid farewell to the limitations of organic film, embrace the power of inorganic technology! Sengu new materials redefines the standard of cave stone with the wisdom of cement chemistry. While competitors are still discussing“Like stone”, we have solved the essential problem of“Whether it is stone”. Sengu new materials, to the source of manufacturers of technical strength, to redefine the standard wall cave stone process, so that the beauty of architecture, durable solid.

Media Contact

Company Name: Sengu (Shandong) New Material Co., LTD.

Email: Send Email

Phone: +86 15562930559

Address:509 Jianshe Road, Tancheng County

City: Linyi

State: Shandong

Country: China

Website: https://www.sengutl.com/