Construction and Operation & Maintenance of Industrial RAS

Industrial Recirculating Aquaculture System (RAS) is an advanced aquaculture model that integrates environmental protection, water resource conservation, and high-density intensification. It represents the future development direction of green and healthy aquaculture technologies in fisheries. Furthermore, it is the only green and healthy aquaculture model capable of ensuring aquatic product safety, free from chemical and heavy metal residues. According to the 2023 China Fishery Statistical Yearbook, China's total industrial freshwater aquaculture output in 2022 was 403,500 tonnes, a year-on-year increase of 24.48%. This article introduces the construction and operation & maintenance technologies for industrial RAS.

1. Key Points of Facility Construction

1.1 Site Selection

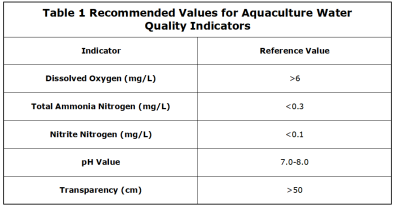

The RAS workshop should be located in areas with convenient water access, good water quality, no flood risk, no pollution, and convenient transportation. Well water is preferable; alternatively, large water sources like rivers, lakes, and reservoirs can be chosen. A natural elevation difference between the water source and the workshop is recommended to reduce energy consumption for water intake. The site ground should be flat with convenient drainage and immediately adjacent to an ecological tail water treatment pond. A rectangular treatment pond is advisable, with a water capacity at least three times the total culture water volume. Site selection must avoid prohibited areas such as "Drinking Water Source Protection Zones" and "Basic Farmland." Recommended values for Aquaculture Water quality indicators are listed inTable 1.

1.2 Culture Area Construction

1.2.1 Culture Tanks

The culture area primarily includes culture tanks, aeration system terminal diffusers, probes for online water quality monitoring devices, bottom drain systems, upflow settlers, side-hill filters, constant temperature pipes, bottom drain pipes, and circulation inlet/return pipes. Culture tanks are recommended to be circular tanks made of galvanized corrugated steel lined with tarpaulin, offering relatively low cost and long service life. Alternatively, PP material circular tanks or brick-concrete square tanks with rounded corners can be chosen, offering long service life and significantly increased water volume per unit area, albeit at a relatively higher cost. Adult fish culture tanks are typically circular tanks with diameters of 8–12 m or square tanks with rounded corners and side lengths of 6–8 m, with a side height of 1.5 m and a bottom cone slope of 15 cm. For ease of manual management, tanks are often installed sunken (0.5–1.0 m below ground) or the working aisles are raised.

1.2.2 In-Tank Equipment Layout

A ring of nano-diffuser tubes should be installed along the inner tank wall, serving as the terminal aeration points for blower mechanical oxygenation. Where conditions permit, placing 2–4 nano-ceramic discs in the tank, using liquid oxygen or an oxygen generator as the source, can effectively increase dissolved oxygen (DO) and enhance the system's carrying capacity. Inlet pipes are placed at opposite sides of the tank to allow simultaneous filling. Inlets should be oriented uniformly and set at a 15–45° angle to the water surface to create maximum flow velocity, facilitating the centralized collection and treatment of particulate matter. For winter culture needs, constant temperature coils can be installed inside the tanks. Screen plates for drain/anti-escape typically have apertures of 3 mm² and 6 mm², and should be changed flexibly according to fish size during the culture period. Bottom drainage is recommended to use a dual-path method: one portion of water is directly discharged from the system as tail water via the bottom drain, and another portion enters the RAS tail water treatment area via an upflow settler or side-hill filter.

1.3 Tail Water Treatment Area

Tail water treatment in RAS typically follows two main approaches: 1) External recirculation using ecological ponds ("Three Ponds and Two Dams") for water purification, or 2) Internal recirculation using water treatment equipment within the workshop, such as microscreen filters, CO₂ degassing units, biofilters, and UV sterilizers. External recirculation primarily consists of a sedimentation pond, an aeration pond, and an ecological purification pond. Filter dams filled with media like volcanic rock are placed between ponds, treating water stepwise through percolation until it meets aquaculture standards before returning it to the culture tanks. This cycle repeats. Its construction cost is relatively low, but it faces challenges with maintaining constant temperature in winter and lacks aquatic plant purification. The internal recirculation process mainly involves removing particulates with a microscreen filter, removing CO₂ and adding oxygen via a CO₂ degassing unit, completing nitrogen removal through microbial action in the biofilter, and finally returning to the culture tanks after UV sterilization, in a continuous cycle. Its initial construction cost is higher. While it facilitates off-season culture, it requires strengthened equipment O&M during management, leading to relatively higher operating costs.

2. System Operation and Maintenance Technology

2.1 Equipment Commissioning

After the RAS is built, all equipment must be commissioned to ensure normal operation. Using the currently mainstream industrial internal recirculation system as an example, key commissioning points are explained below. Operators can refer to these based on their own system setup. Commissioning includes: checking blower and oxygen generator output and diffuser uniformity in tanks; adjusting water output of circulation pumps using VFDs; testing physical water passage capacity of sand filters; verifying normal operation of UV sterilizer lamps; checking control functionality of central control system switches; adjusting feeding area and spread height of automatic feeders; setting backwash timing and frequency for microscreen filters; ensuring normal operation of CO₂ degassers; adjusting ozone aeration, water discharge, and foam production in protein skimmers; checking fluidization state of biofilter media; adjusting water inlet angles in culture tanks; and verifying automatic start/stop of drain valves. After commissioning, fill the system, initiate circulation for a trial run, check for pipe leaks, and perform timely repairs. After successful commissioning, thoroughly clean the workshop floor and walls to maintain cleanliness.

2.2 Tail Water Treatment Bio-preparation

2.2.1 External Recirculation Systems

For external systems, tail water treatment focuses on the ecological pond. Aquatic plants need key attention for cultivation in the biological purification zone. Prepare and cultivate these plants in advance according to their specific planting seasons and the aquaculture schedule, aiming for maximum planting density and area within the pond. Rice can be chosen for cultivation. In case of water quality deterioration, economically valuable crops like water spinach or water celery can be planted to purify water while enhancing economic returns. During water quality issues, combine with water quality adjustment measures and further increase plant biomass.

2.2.2 Internal Recirculation Systems

Internal systems involve biofilter media maturation. Generally, before starting culture, the biofilter should be pre-matured to establish some capacity for degrading ammonia and nitrite nitrogen. During maturation, dissolve and add 80–100 g/m³ of compound feed (crude protein ≥40%) and 2–5 g/m³ of compound nitrifying bacterial powder daily to supplement nitrogen and carbon sources, aiding nitrifier proliferation. Typically, after 20–30 days, the biofilter preliminarily possesses the ability to degrade ammonia and nitrite nitrogen, and can then be integrated into the circulation loop to begin stocking.

2.3 Circulation Rate Adjustment

In the early culture stage, conventional fish fry are small. It is recommended to operate the first 10 days without water recirculation, using flow-through culture with daily water exchange. The daily exchange rate can be 30%–70%, depending on water quality. After the fish stock stabilizes, use pump VFDs to adjust the recirculation rate. Initially, 1–2 full system volume exchanges per day are recommended. As the fish grow, gradually increase the recirculation rate until reaching the maximum, typically >8 exchanges per day for conventional adult fish culture. During the culture process, increases in daily exchange frequency should primarily be based on levels of ammonia nitrogen, nitrite nitrogen, and suspended solids. When these exceed preset safe ranges, increase the recirculation rate to maintain a safe and stable water environment.

2.4 Equipment Inspection

After stocking, perform daily equipment inspections and record key operating parameters. Inspections should include: checking blower and oxygen generator pipes for leaks, unusual noises, and diffuser uniformity in tanks; examining circulation pump operation and normal start/stop of level control valves; verifying microscreen filter backwash operation and membrane permeability; checking media fluidization state in the biofilter and effluent purification effect; inspecting UV sterilizer lamp brightness and cleaning lamp exteriors regularly; checking the normalcy of online water quality monitoring indicators and cleaning probes periodically. Also, record daily water and electricity usage for subsequent analysis and review.

2.5 Feeding and Waste Discharge

In industrial RAS, daily feeding and waste discharge are crucial for maintaining stable water quality and healthy fish growth. For manual feeding, use fixed locations away from high-flow inlet areas, preferably in calm flow zones outside a radius of 1.5–2.0 m from the tank center, also avoiding concentrated aeration zones, and feed consistently from these spots. For automatic feeding, adjust the feeder nozzle spread to avoid the central waste collection zone, aiming for the maximum spread area. The number of daily waste discharges can be set based on feeding parameters. Generally, initiate discharge 1–2 hours after feeding, with each discharge lasting 15–45 seconds. During culture, the specific duration for each discharge can be determined by observing the time taken for concentrated waste to be expelled via the bottom drain, adjusting this every 1–2 weeks.

3. Conclusion

The industrial RAS centers around tail water treatment, combined with the functional support of various facilities and equipment, to maintain suitable water environmental conditions for fish. It can actively contribute to ecological tail water treatment, water resource conservation, and environmental protection. During its operation, primary attention should be paid to the water purification capacity of the tail water treatment area. Based on water quality indicators and fish status, promptly adjust the recirculation rate to keep water quality parameters within safe levels, thereby promoting healthy, rapid fish growth and achieving high yields and income.

Media Contact

Company Name: Hangzhou Juntai Plastic Products Co., Ltd.

Email: Send Email

Country: China

Website: https://www.juntaienviro.com/